Pulse echo technology is a constantly evolving piece of technology in NDT Global’s portfolio.

These tools were built for a purpose: to collect high resolution data that can be used to monitor metal loss in your pipelines. Highlighting our commitment to innovation, the most recent iteration of this technology can detect sizing tolerances down to 0.4 mm (0.02 in.), a two-fold advancement over the last generation. These technological advancement were made (and are continuing to be made) in our effort to give asset owners the most precise insights possible so they prioritize pipeline remediation efforts without needlessly spending on threats that won’t reach burst pressure until far in the future. Pulse echo is a unique instance of ultrasonic technology because it delivers direct metal loss measurements.

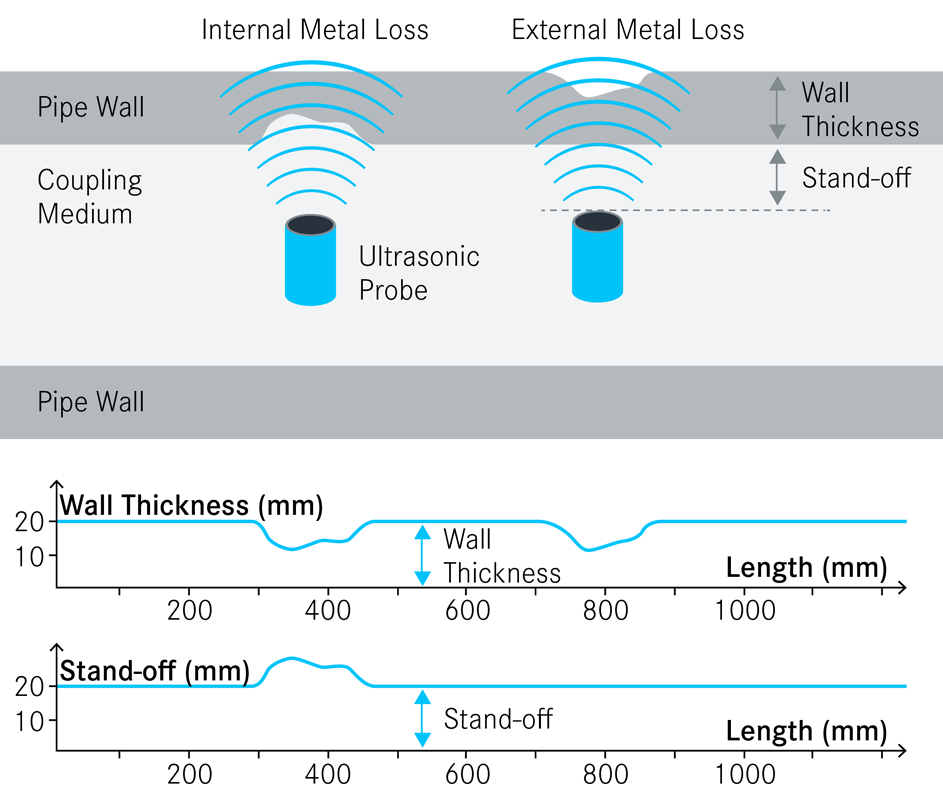

Instead of expressing metal loss as a percentage of pipe wall thickness, asset owners get the exact measurements of metal loss features. This is accomplished by using a single transducer to both send out a signal and receive it. It sends out a zero-degree compression wave and then measures the time-of-flight differential between the transducer and the backwave echo to determine length, width, and depth of potential metal loss. The high-resolution metal loss data acquired from the tool is analyzed by highly qualified engineers who also differentiate between diverse lamination types, i.e. sloping or surface breaking laminations, providing a more complete picture of an asset’s health.