We are delighted to announce the forthcoming upgrade of NDT Global's Ultrasonic Geometry service. This upgrade is in line with the recently presented PRCI's* Dent Fatigue Life Assessment methodology. This approach offers less conservative assessments, not only using the depth and length of the dent, but the actual shape of the dent, giving pipeline operators parameters for dent prioritization and dent fatigue life assessment.

News

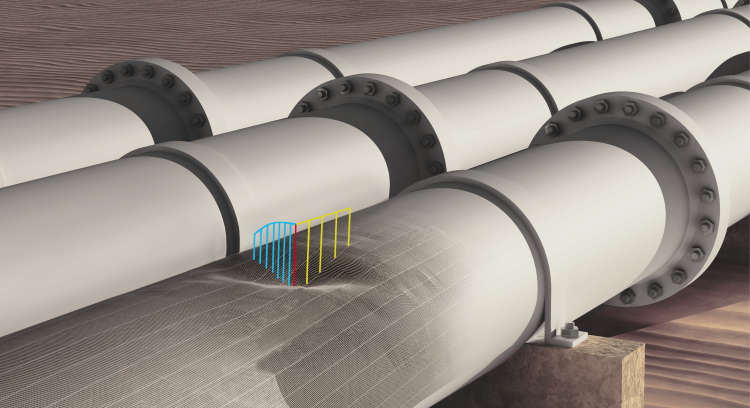

Upgrade of the Ultrasonic Geometry Assessment Methodology

This service extension is a great fit to the Ultrasonic Geometry inspection, currently delivering accurate and reliable ultrasonic inline inspection data by combining a corrosion or crack assessment with an ultrasonic based geometry measurement. Using ultrasonic technology ensures precise, direct measurement of dents with depth resolution down to 0.1 mm (0.004 in.).

*Pipeline Research Council International: www.prci.org

Discover the Power of Clarity.

Whether you’re ready to schedule an inspection or have questions about our process, our team can help get you started.

Contact Us© Copyright 2026. NDT Global. All Rights Reserved.