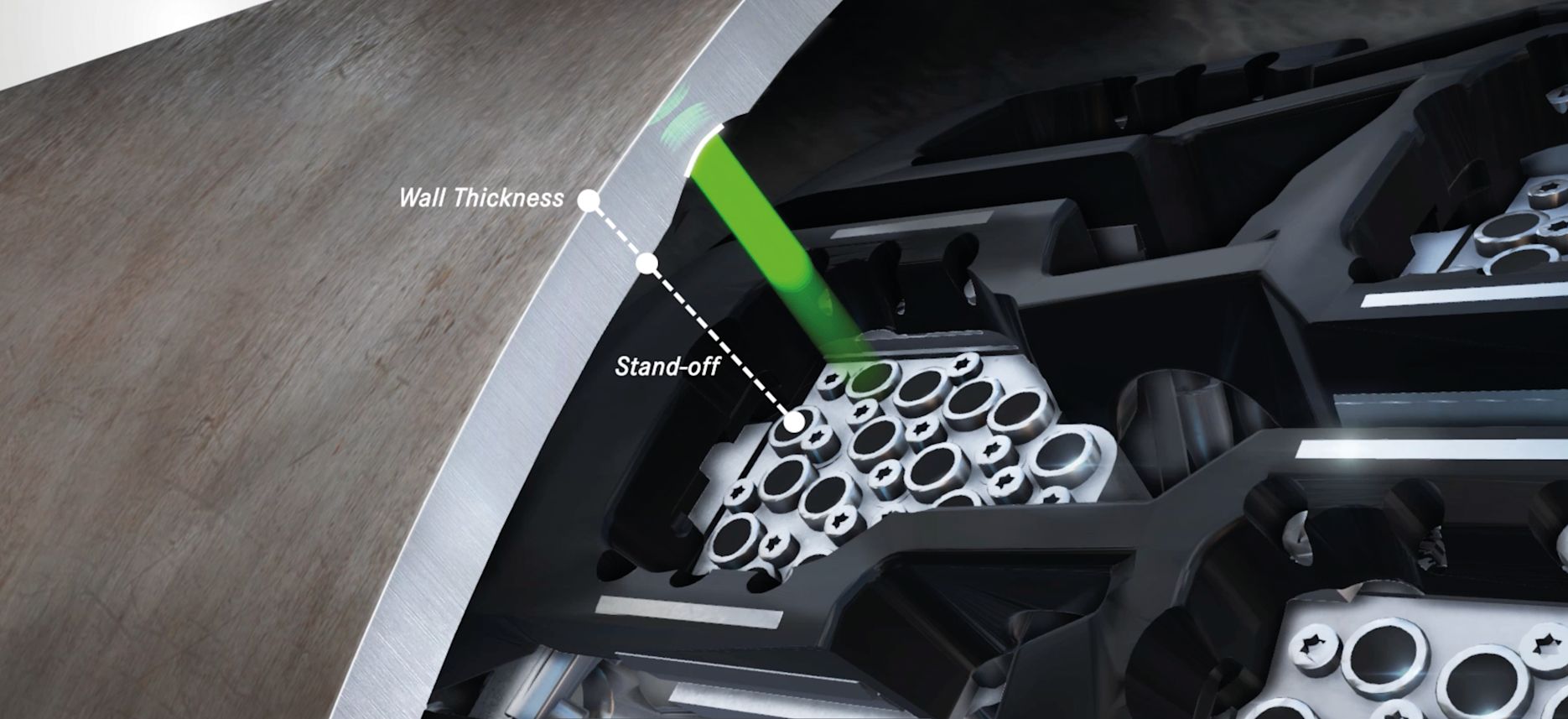

A major pipeline operator and client of NDT Global required support and advice to safely complete an ultrasonic inline crack and metal loss inspection on their 10”, 1.25 mile (2 km) feeder pipeline running 100% liquid ethanol. Although an untested medium for an ultrasonic inspection, the customer was determined to find a way to replicate the high-resolution and accurate pipeline inspection they achieve in all other lines using NDT Global’s ultrasonic technology. By its nature, liquid ethanol is considered to be a volatile product when compared to crude oil or refined products such as diesel. To fully understand inspection parameters, the liquid ethanol was sampled and tested, identifying properties and initiating a review of viable inspection options. Following previous successful inspections in other mediums such as propane and butane, NDT Global’s engineering team determined that without tool customization, the unique properties of ethanol would not be viable to complete an ultrasonic crack inspection. When used in liquid ethanol, the typical arrangement of tool sensors cannot achieve the required angle of incidence to accurately inspect the line.

Case Study

Ultrasonic Inline Inspection for Ethanol Pipelines

The Challenge

The Solution

Following further investigations, to successfully begin the ILI process, NDT Global’s team proposed an ultrasonic wall thickness measurement inspection. Using ultrasonic technology, an accurate and reliable ILI was performed. As ethanol is an extremely flammable clear liquid which evaporates quickly, the engineering team diligently prepared for this inspection. Additional field safety processes included a nitrogen flush, before and after the tool was inserted and removed, and ethanol air testing equipment was used to monitor the levels of ethanol vapors. Once the ILI inspection was complete, NDT Global’s data analysis experts analyzed the results and prepared a detailed assessment report of the line. Following the successful metal loss inspections, the operator worked with NDT Global to create a tailored solution for the successful completion of ultrasonic crack inspections in this line. Through close correlation, dedication, safety awareness and a willingness to push the boundaries, the operator is successfully completing both ultrasonic metal loss and crack assessments in this ethanol line.

The Results

Customized solution: Following the successful metal loss inspections, the operator completed

crack assessments in this line. To date, three successful crack and two metal loss inspections have been performed in the ethanol environment. These inspections enhanced the client’s integrity program.

Regular inspections possible: The client now includes these feeder lines in their overall

integrity program. The inspections have achieved leading industry detection, sizing and

performance specifications.

Trusted ILI partnership: Addressing this unique situation with determination until a solution was reached, enabled the operator to achieve the same high standard of ILI in their ethanol lines as they do in their other lines. With NDT Global the operator is confident that their inspection is leveraged to improve pipeline integrity, save operational costs, extend pipeline life, and most importantly, preserve the environment and surrounding communities.

Discover the Power of Clarity.

Whether you’re ready to schedule an inspection or have questions about our process, our team can help get you started.

Contact Us© Copyright 2025. NDT Global. All Rights Reserved.