In 2019 a Canadian pipeline operator approached NDT Global to better understand the integrity of two 12" pipeline segments totaling 290 km (180 miles) within their natural gas system. Previous inspections utilizing alternative inspection technologies identified possible cracking threats, but a more detailed inspection was required to confirm the extent of the threats they needed to remediate. By successfully applying ultrasonic inspection technology, the operator could gather a full range of potential indications in both the pipe body and long seam locations.

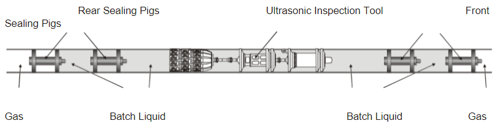

The challenge with applying a UT based inspection technology in a gas pipeline is the requirement of a liquid coupling medium to ensure compatibility of the UT crack detection technology. Inserting a liquid into a gas pipeline is costly and not an ideal situation for operators. With stringent requirements for their customer’s delivered gas, outage times on the system can create impacts to downstream delivery points.

It is also important to consider the type of liquid used as each will have varying degrees of requirements to ensure the return to full gas operation is smooth with no degradation to the product being delivered.