A major US operator faced the challenge of connecting a deepwater oil export line to an existing 24"/28" multi-diameter oil export route in the US Gulf of Mexico. There was a strong desire to use a 16" export pipeline to reduce project installation costs. With these extreme conditions, pigging through varying geometries was considered impossible with any commercially available ILI tools. To successfully inspect the line would require a tool to reliably travel through the new 16" pipeline into an existing 24"/28" multi-diameter pipeline. Aside from unprecedented diameter variations, the system includes several challenging top-entry wye geometries. Overall, it was confirmed that a customized inspection tool for this challenging pipeline system was required.

Case Study

Custom Engineered Baseline Inline Inspection for Multi-Diameter Oil Export Route

The Challenge

The Solution

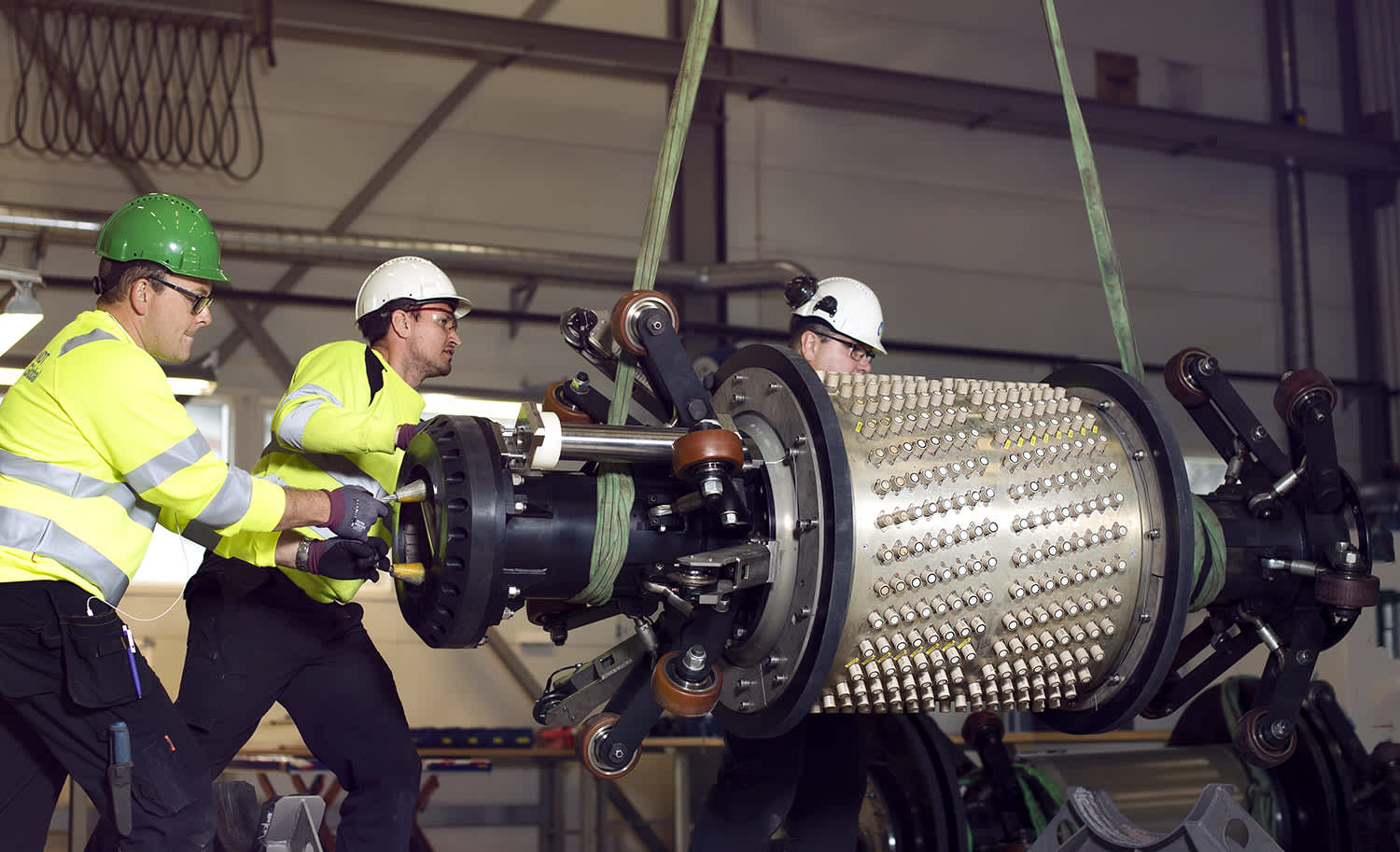

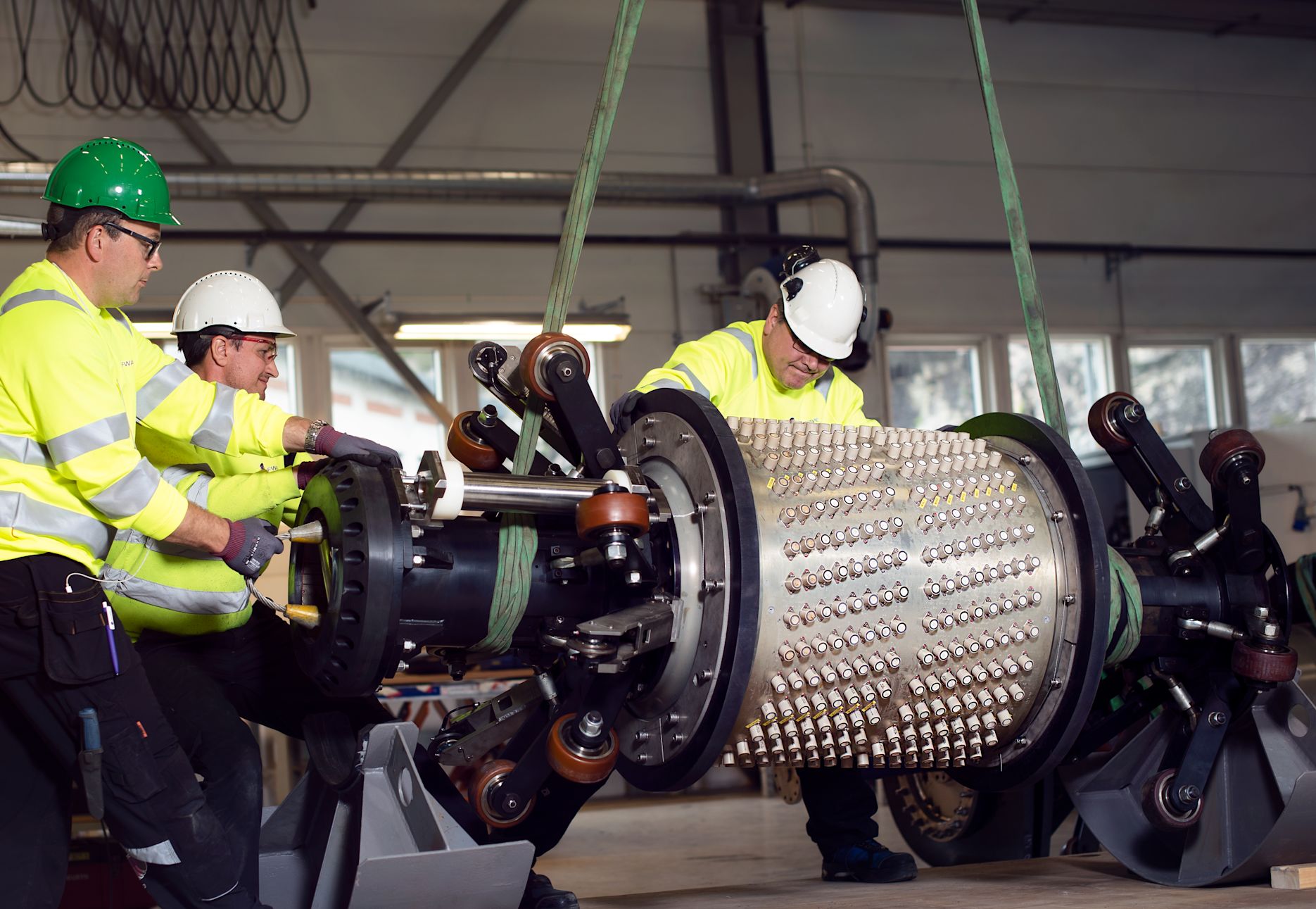

To inspect this complex line, we worked together with the operator to launch an intensive development program focusing specifically on safe passage through the entire pipeline system, while maximizing measurement accuracy. The end result is a lightweight and low-drag ART Scan™ inline inspection tool for extreme diameter changes. NDT Global’s acoustic resonance technology (ART) successfully overcame the pigging challenges, while also providing best- in-class accuracy for both internal and external metal loss features, and geometry. Typical stand-off requirements for ART sensors range from 100 mm to 250 mm (4 in to 10 in). A typical ART Scan tool has two main sections separated by a single flexible joint. The first section includes seal discs and batteries, while the second section houses the transducers and electronics, all in a single body. The key to the success of ART technology is ensuring that the tool is always centralized to enable the accurate measurement of wall thickness, geometry and any metal loss. This is achieved using dedicated spring-mounted wheels on each tool section.

The Results

Specialized tool build: A highly customized ILI tool was designed, built and qualified to overcome the challenges posed by this pipeline system with an extensive range in diameters, as well as numerous challenging wye transitions.

Future integrity program: This customized tool paved the way for future inspections and enables the operator a thorough view of the integrity of this and future lines .

Successful baseline inspection: Due to the successful completion of this customized tool, this asset in the Gulf of Mexico is expected to start production in 2021, from a new floating production platform, installed in > 4,500 ft water depth.

Discover the Power of Clarity.

Whether you’re ready to schedule an inspection or have questions about our process, our team can help get you started.

Contact Us© Copyright 2025. NDT Global. All Rights Reserved. - NDT Global is a Previan Business Unit