Pipeline operators often employ various techniques to ensure the safety of their pipeline systems, including inline inspection (ILI) and non-destructive examination (NDE). However, detecting and characterizing complex cracks,

such as hook cracks, in low-frequency electric resistance welded (LF-ERW) pipes pose significant challenges. These challenges are exacerbated by the limitations in the performance specifications of available ILI tools. This is particularly true for small-diameter pipes, and the complexity of crack geometries. Hook cracks are difficult to detect and size accurately due to their non-radial orientation and the presence of impurities in vintage pipelines.

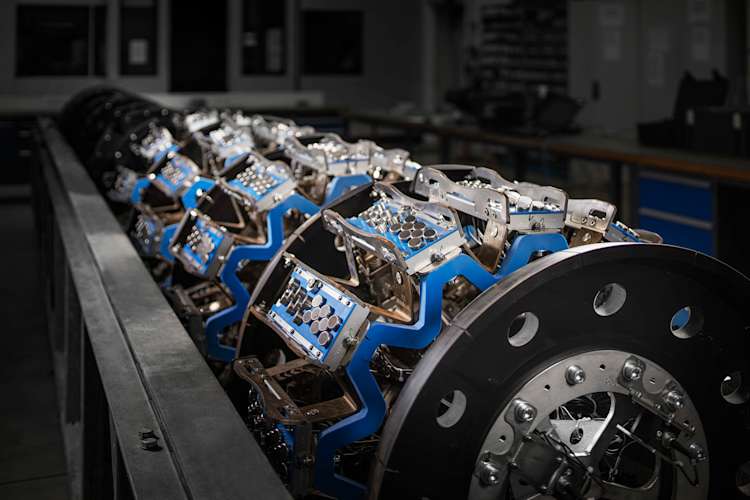

In December 2021, a high-resolution axial crack inspection was conducted on a 6" pipeline constructed before 1970. The inspection revealed numerous anomalies, including hook cracks, which standard ILI tools struggled to accurately size and characterize due to their complex geometries and the small diameter of the pipeline