An oil and gas exploration, development and production company required assistance verifying field anomalies on its 24" above ground pipeline.

The customer was in the process of a multi-year thermal development program as this project is a thermal in situ operation that produces > 50,000 barrels per day. As the line transports hot fluid it experiences large temperature changes. It is well isolated and includes a high number of bends to allow expansion. Deposits appear in the form of bitumen, which in its natural state is too viscous to flow. When bitumen is too deep (> 80 m) to economically mine, steam is injected to warm it. This reduces the viscosity and allows it to be pumped through surface wells.

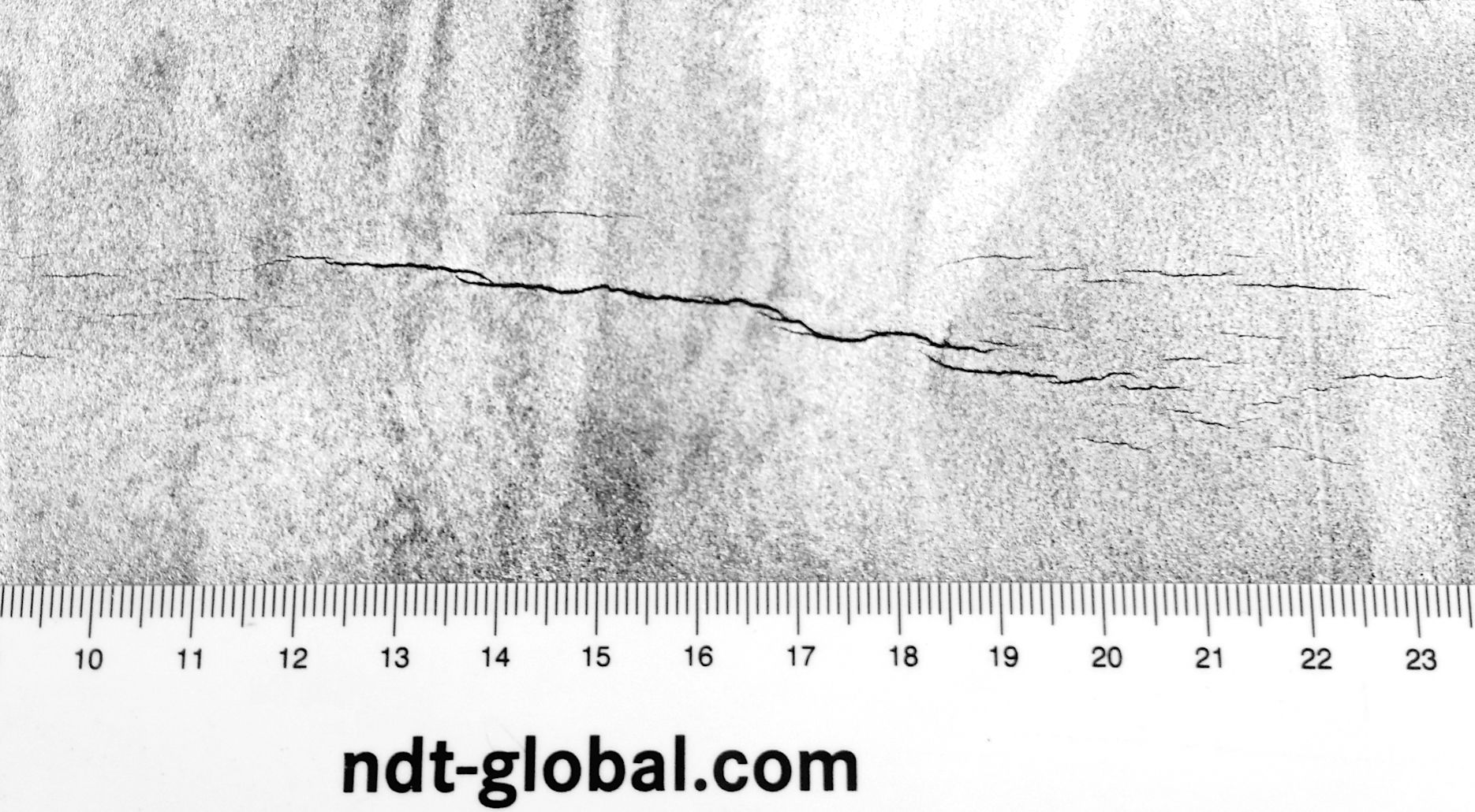

Field investigations of this line identified cracking features. The presence of such features determined a possibility that some features located within bends had exhibited axial/circumferential cracking with complex angles. Because of this, time was now a main concern for all consecutive actions. A streamlined repair schedule was required to bring this line back into service as soon as possible.

This would be the first completed inspection for the line, which has been operational for six years and would form a starting point for ongoing integrity management. Although no previous projects were completed for this customer, NDT Global was chosen based on a reputation for customer service, accuracy and quality data analysis.