Equinor, a North Sea operator, required an inline inspection of a subsea pipeline used for transporting gas and gas condensate from a subsea template to a platform that was essential to the company’s ongoing operations. To assess the conditions of the critical parts of this asset, which had never been inspected, 720 m of 10" diameter flexible riser and end fittings needed to be examined.

The flexible riser starts at the platform and descends 322 m (1056 ft) to the seabed, where it connects via end fittings to a 6.5 km (4.04 mi) long, 10" diameter subsea pipeline and ends at a subsea template. Due to the system layout, a bi-directional inspection tool was required to complete the inspection.

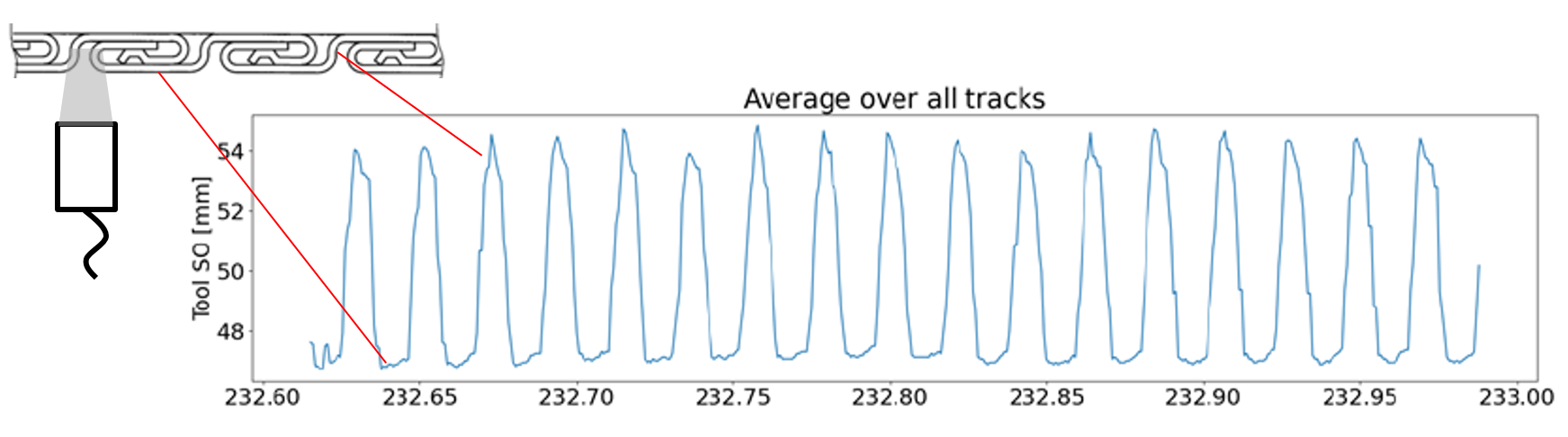

To obtain reliable data about the condition of this pipeline section, the chosen inline inspection (ILI) solution must be capable of performing a high-resolution measurement of the pitch between the carcasses throughout the length of the riser, and the critical end couplings, as well as the end fitting positions.