Choosing the Right Pipeline Technology

The oil and gas pipeline industry has witnessed an impressive evolution of pipeline inspection and maintenance technologies, from rudimentary techniques to advanced testing methods. These technological leaps have enhanced safety, efficiency, and integrity across the industry.

The Role of Technology

Choosing the right inspection technology is pivotal to exceeding industry standards, ensuring safety, and driving economic value. Different scenarios necessitate distinct technologies and demand specific capabilities, from land-based pipelines that cross vastly different terrains, both above and underground, to undersea pipelines.

Certain challenges call for a more granular approach, such as Integrity Consulting Services from NDT Global. These services offer a comprehensive scope to dig deep into historical data and uncover deeper insights. Leading-edge software lets us create customized analyses of data.

Pipeline condition also plays a substantial role when it comes to crack detection, pipeline movement, or corrosion. Various non-destructive testing (NDT) and inline inspection (ILI) methods are used in the industry today. Examples include Electromagnetic Acoustic Transducer (EMAT), multiple Ultrasonic Testing (UT) techniques, magnetic flux leakage (MFL), and Visual Testing (VT).

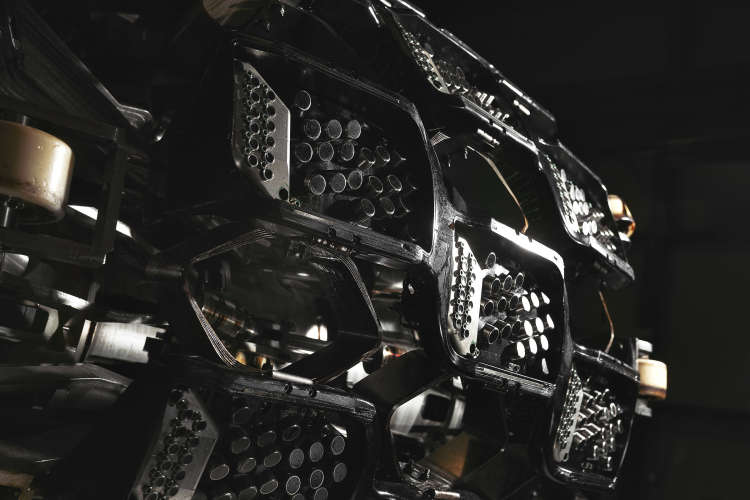

UT, applied in ILI, has demonstrated exceptional prowess in assessing wall thickness, detecting and sizing cracks, inspecting diverse materials, and providing high-resolution data insights. With its industry-leading expertise, NDT Global excels in delivering unparalleled integrity solutions that cater to the most demanding industry needs.

A Closer Look at Ultrasonic Testing

UT has become the go-to technology for many companies. The accuracy of UT, its ability to pinpoint cracks and delineate anomalies, and its sensitivity to pipeline flaws set it apart from other testing methods. It equips pipeline operators and integrity managers with a comprehensive pipeline overview, aiding in risk management, contingency planning, and future infrastructure replacement.

The utility of UT is unmatched, allowing operators to identify even minute defects. It provides an anomaly's exact location, shape, and size, furnishing a precise pipeline health snapshot. This enhances reliability and reduces the potential for pipeline failures and digs.

UT has proven its value and continues to pave the way forward, offering unprecedented accuracy and a complete diagnostic view. Its superiority is further exemplified in its flexibility and adaptability to various scenarios, thanks to the different types available. Types include Phased Array UT (PAUT), an advanced method that offers a complete volumetric examination of a pipeline, and Time-of-Flight Diffraction (TOFD), a technique used to measure pipeline welds accurately.

The non-intrusive nature of UT is essential, providing high-resolution results, minimizing downtime, and maximizing productivity. Moreover, the versatility of UT extends to all types of pipelines. It effectively detects potential issues regardless of the materials used. Companies can use UT across their entire pipeline infrastructure, which adds to its economic efficiency.

UT’s accurate and detailed analyses provide the critical data needed for optimal maintenance decisions, preventing unnecessary and costly interventions. These insights are not just beneficial – they are essential for the successful, long-term operation of any pipeline asset. Complex data and an accurate historical record of pipeline integrity empower better decision-making and give pipeline operators the insights to predict potential problems.

Zero in on the Right Technology

Choosing inline inspection technology is about more than meeting immediate inspection needs; it's about finding a solution that offers accuracy, longevity, flexibility, and adaptability. Selecting the right technology is a critical decision that impacts your business's viability, environmental safety, and people's lives.

NDT Global brings the Power of Clarity to your decision-making process with cutting-edge technology, superior insights, and industry-leading expertise. To us, it's not just about technology; it’s about how we use it to provide you with decision-ready data at your fingertips.