With this “short list” of dents and/or dentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal.-like anomalies, NDT Global’s team of experts look at the data through a few, targeted lenses intended to inform an operatorAn entity or organization responsible for the operation, management, and maintenance of a pipeline system. The operator is entrusted with ensuring the safe, rel…’s dent mitigationAppropriate action based on an assessment of risk factors to reduce the overall level of pipeline integrity risk by reducing the amount of risk from a probabili… and remediationThe appropriate actions taken to address or rectify issues, deficiencies, or anomalies identified in a pipeline system. It involves implementing corrective acti… plans. The first insight we produce is regarding the dent’s failureThe inability of a pipeline system to fulfill its intended function or meet the required performance criteria. Pipeline failures can have significant consequenc… pressure. With an understanding of failure pressure, it’s possible to predict a range of future maximum operating pressureThe maximum pressure that a pipeline or pressure vessel is designed to safely handle during normal operation. It represents the highest pressure that the system… growth beyond which pipeline failure can occur. In addition, we analyze inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… data to observe where the asset is in its fatigueThe process where cracks develop and propagate in a material under cyclic loading or repeated stress over time. It is a type of fatigue failure that occurs when… life; when compared to this estimation, it’s possible to predict a range of time within which a dent in the asset can cause the premature end of an operation’s useful life.

The types of integrityThe capability of a pipeline to perform its intended function safely and reliably throughout its life. It includes a range of factors, including the structural … assessments needed before plans can be solidified are based on a number of factors including things like the physical location of the pipeline in question, immediate integrity, future integrity, the presence of coincidental features, and pipeline manufacturing methodology. These factors should be combined with predicted failureThe inability of a pipeline system to fulfill its intended function or meet the required performance criteria. Pipeline failures can have significant consequenc… rate and maximum operating pressureThe maximum pressure that a pipeline or pressure vessel is designed to safely handle during normal operation. It represents the highest pressure that the system… to inform remediationThe appropriate actions taken to address or rectify issues, deficiencies, or anomalies identified in a pipeline system. It involves implementing corrective acti… plans that will maximize an asset’s safety, throughput, and profitability.

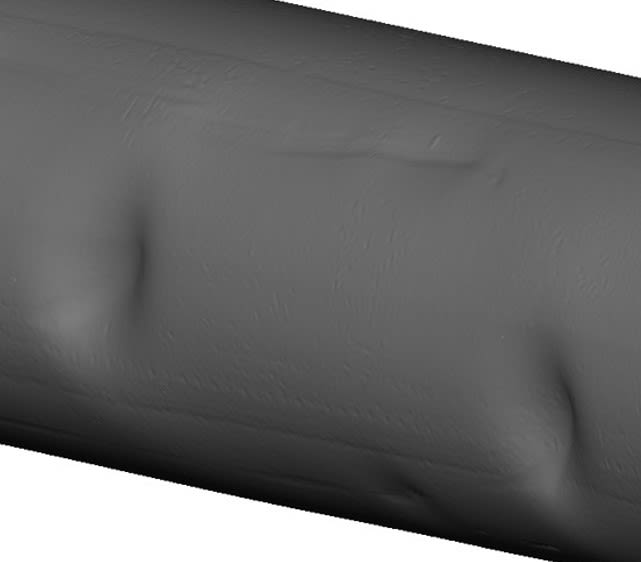

While establishing the rough condition of a dentA local change in pipe surface contour caused by an external force such as mechanical impact or rock impingement but is not accompanied by loss of metal. at the beginning of a dent characterization assessment is important, it becomes critical to get the highest resolution picture of its size, depth, orientation, and the condition of its ability to endure high pressure as these observations move closer to causing real-world actions.