Historically, multi-diameter inspections have presented challenges which would have been difficult to address for ILI solutions.

Pipelines with large diameter variations and wye transitions, for example, made inspecting these systems a risky, expensive endeavor with an exceedingly high probability of failure. Our response was to adapt the ART Scan™ platform, enabling it to successfully inspect these pipelines with minimal risk and at minimal disruption to your operation.

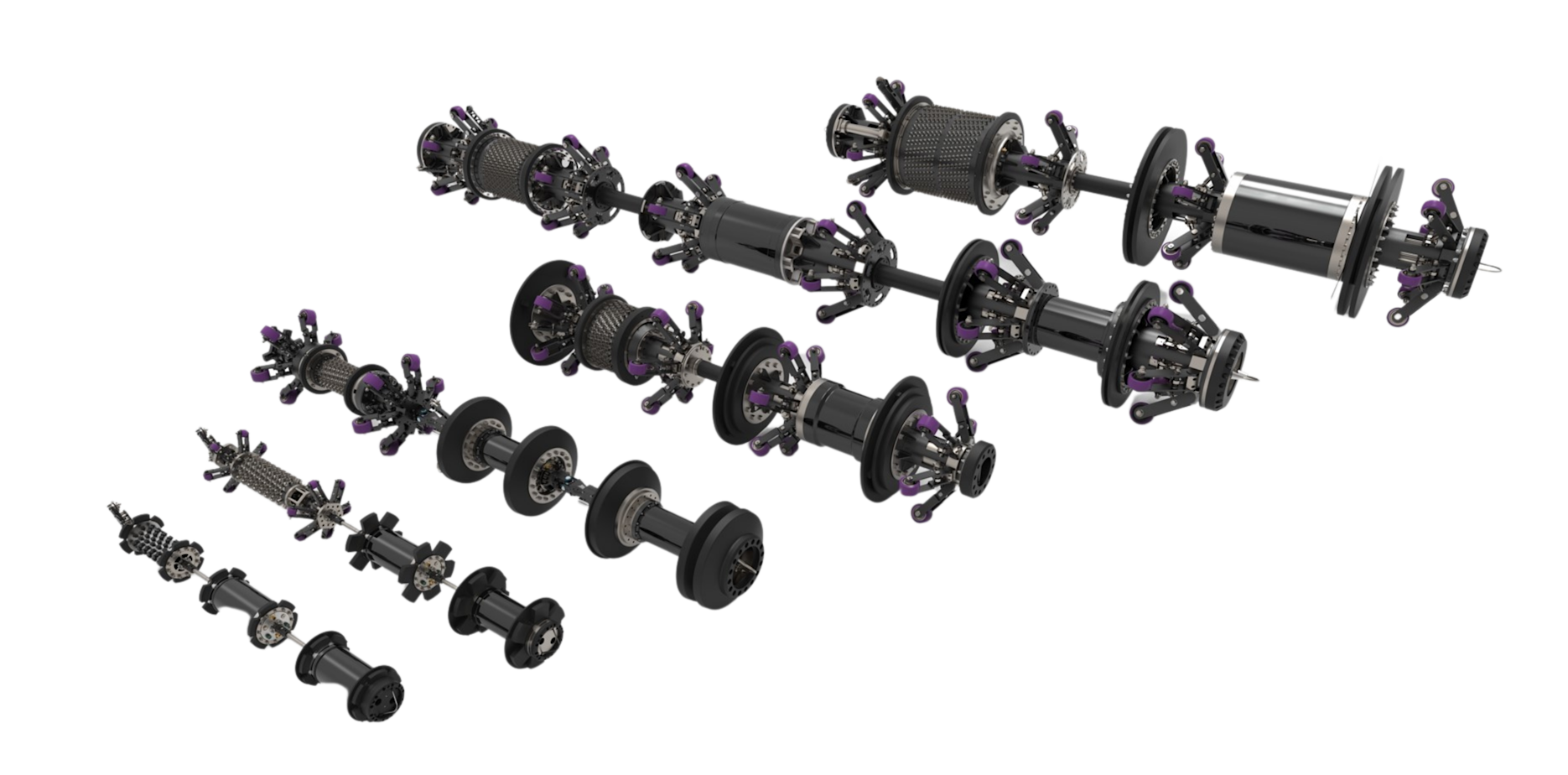

ART Scan’s high first-run success rates in a multi-diameter environment can be traced back to its design. First, the tool’s efficient design features a large sensor standoff that’s capable of negotiating and inspecting wye passages and pipelines with diameter changes of 50% or more. Second, ART Scan is a non-contact inspection technology, which ensures the safety of your pipeline while simultaneously increasing inspection speed. Finally, using ART Scan eliminates the need and the cost of developing a customized tool for multi-diameter pipelines; our tools were designed to inspect these pipelines with minimal customization. All of these characteristics combine with ART Scan’s incredible data collection accuracy so that customers get the best data in the most efficient manner.