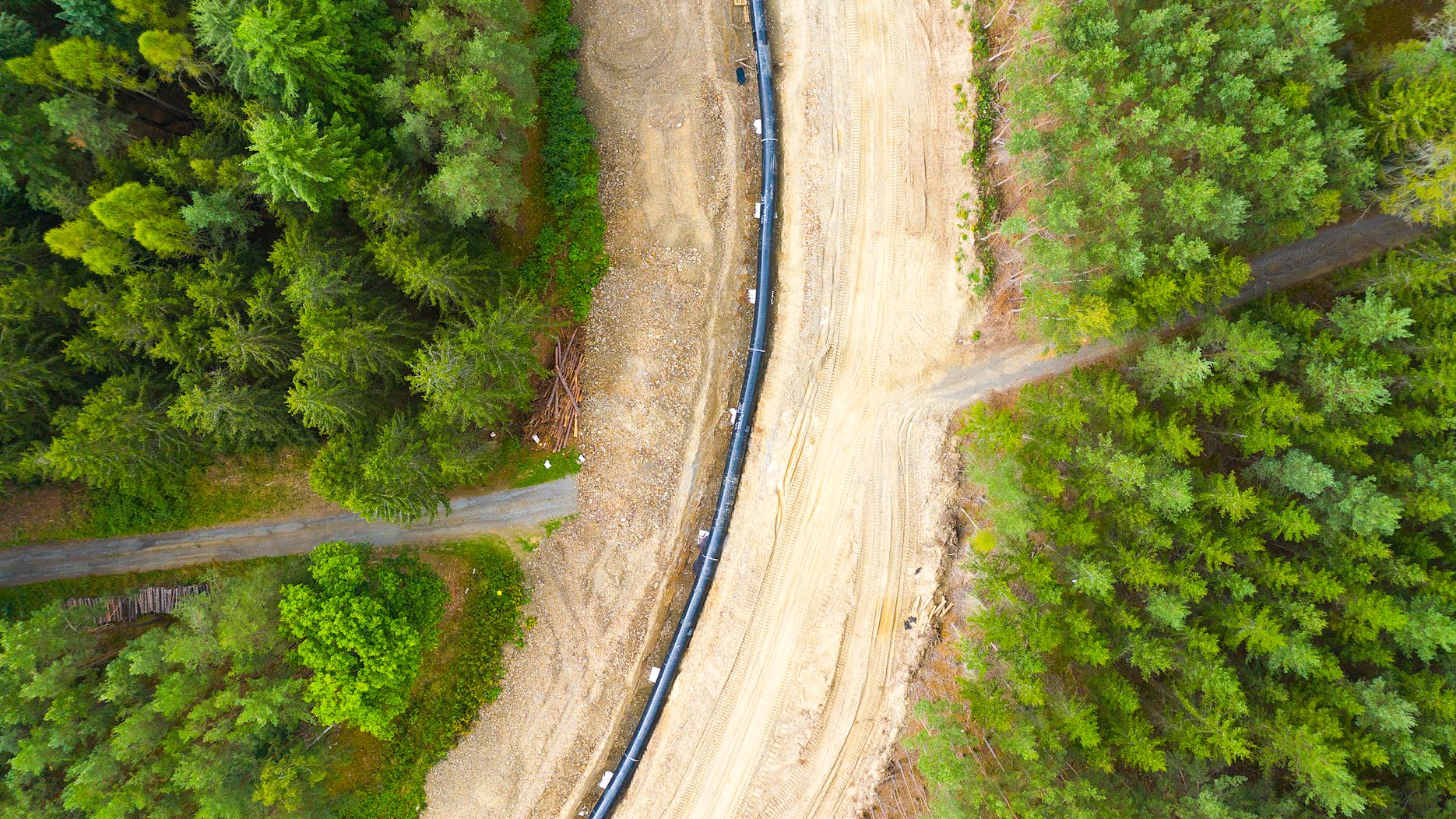

Following the INS, our next two analyses are the Pipeline StrainRefers to the stress and deformation that a pipeline experiences due to external forces, such as ground movement, soil settlement, or external loading.

When … and Run-on-run

Strain Comparison reports. Using the data gathered in the INS, the Pipeline Strain analysis looks at areas of a pipeline where measurements are above the system’s expected average. These differences can be correlational to the possibility of buckles and cracks. Left unattended, these anomalies can result in pipeline failureThe inability of a pipeline system to fulfill its intended function or meet the required performance criteria. Pipeline failures can have significant consequenc…, environmental damage, and financial loss. But with the data our analysis provides – to within millimeters’ accuracy – operators have the information they need to proactively deal with these features before they become crises.

An additional solution that NDT Global offers is an ultrasonic circumferential crack detection tool. Combined with INS data, circumferentialAn event that occurs or is measured along the circumference of a pipeline. It implies the direction or orientation that is perpendicular to the longitudinal axi… crackA fracture or discontinuity in the wall of a pipeline, where the material is separated or broken, potentially compromising the integrity and safety of the pipel… data offers even deeper insight into potential anomalies in your pipeline, particularly those associated with joints and welds. Cracks at these locations have the potential to be the most injurious, so early and accurate identification is critical. The result of this combined inspectionThe systematic process of visually examining, testing, or monitoring pipeline components to assess their condition, integrity, and compliance with regulatory re… method is a set of insights that give a view into how likely buckles or circumferential cracks might be. With this information in hand, customers have the ability to confidently execute integrityThe capability of a pipeline to perform its intended function safely and reliably throughout its life. It includes a range of factors, including the structural … management programs for pipelines prone to strainRefers to the stress and deformation that a pipeline experiences due to external forces, such as ground movement, soil settlement, or external loading.

When … caused by movement.

If Pipeline Movement is within the scope of your pipeline integrity management programA documented set of policies, processes, and procedures implemented by operators to ensure the safe, reliable, and efficient operation of pipelines throughout t…, contact NDT Global to learn how we can offer best-in-class solutions.